Department of Design and Construction311

Department of Design and Construction311 Search all NYC.gov websites

Search all NYC.gov websites

Sewers and South Street

There are over 7,400 miles of sewage pipes running underneath New York City. This massive network collects and transports wastewater from your drains and stormwater from the streets. Our sewer network is key to keeping the City clean and dry, but due to its age, it also requires consistent maintenance.

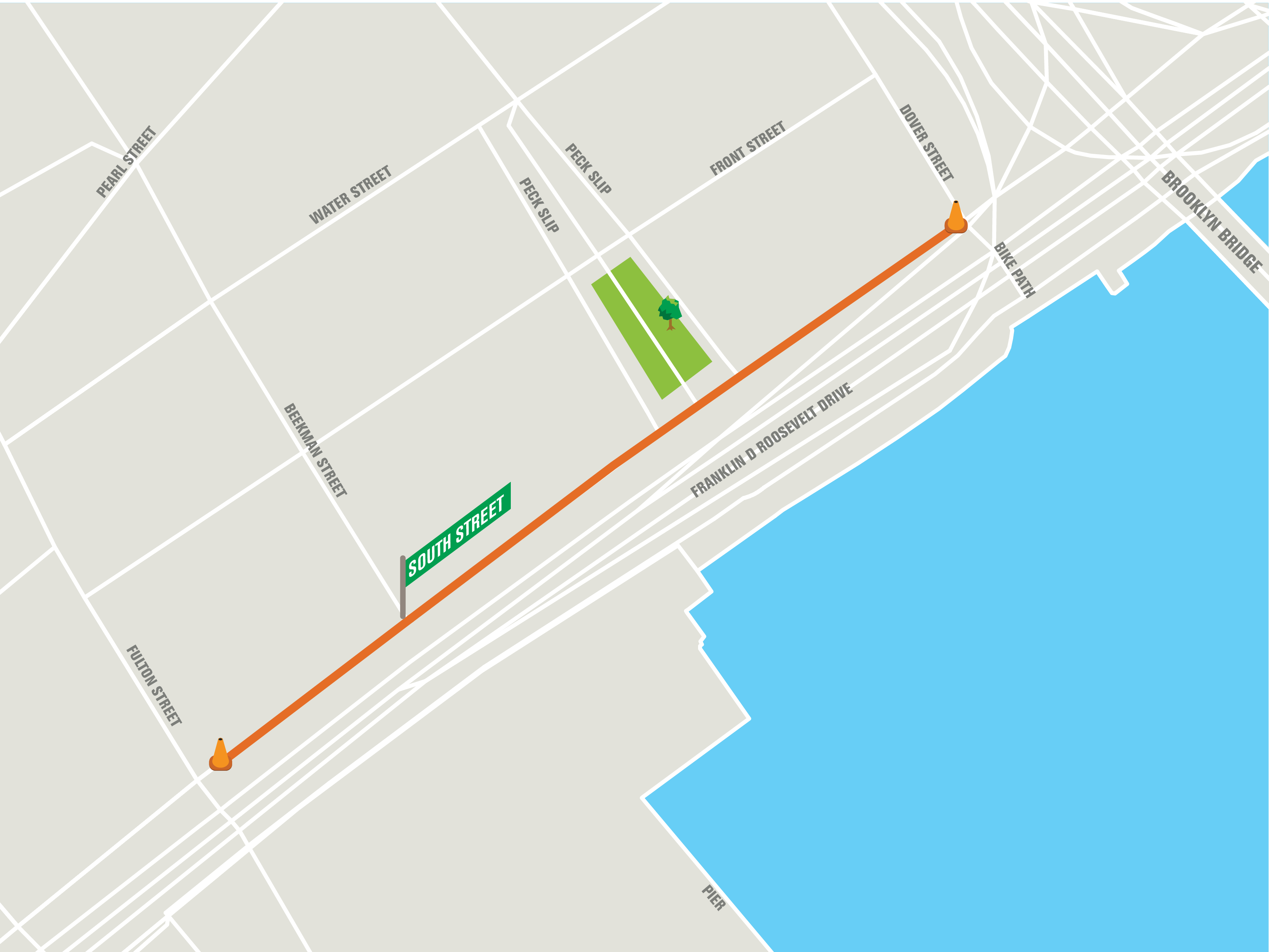

DDC works alongside our partner agencies to find fast and cost-effective ways to help our sewer system do its job. A current example of that effort can be found near the South Street Seaport, where DDC is managing the rehabilitation of a major interceptor sewer. Interceptors are large sewer lines that receive water from multiple smaller pipes and direct it towards a treatment facility. The project was initiated because the concrete walls of the South Street interceptor sewer are wearing down, making it vulnerable to infiltration from the East River and therefore more likely to overflow.

The South Street rehabilitation project is the first in New York City to utilize a method known as spiral wound lining. The spiral wound lining process does not require workers to excavate a trench and expose the interceptor sewer. Since digging a trench requires extensive road closures and the disruption of various utility lines, trenchless methods save time and are more convenient for residents.

Other trenchless rehabilitation projects generally use a resin material that can create an unpleasant odor and is time consuming to cure, but the spiral wound lining method is entirely mechanical, with no need for resin. This allows work to stop and start as needed and means there is no need to dispose of any contaminated water once the project is complete.

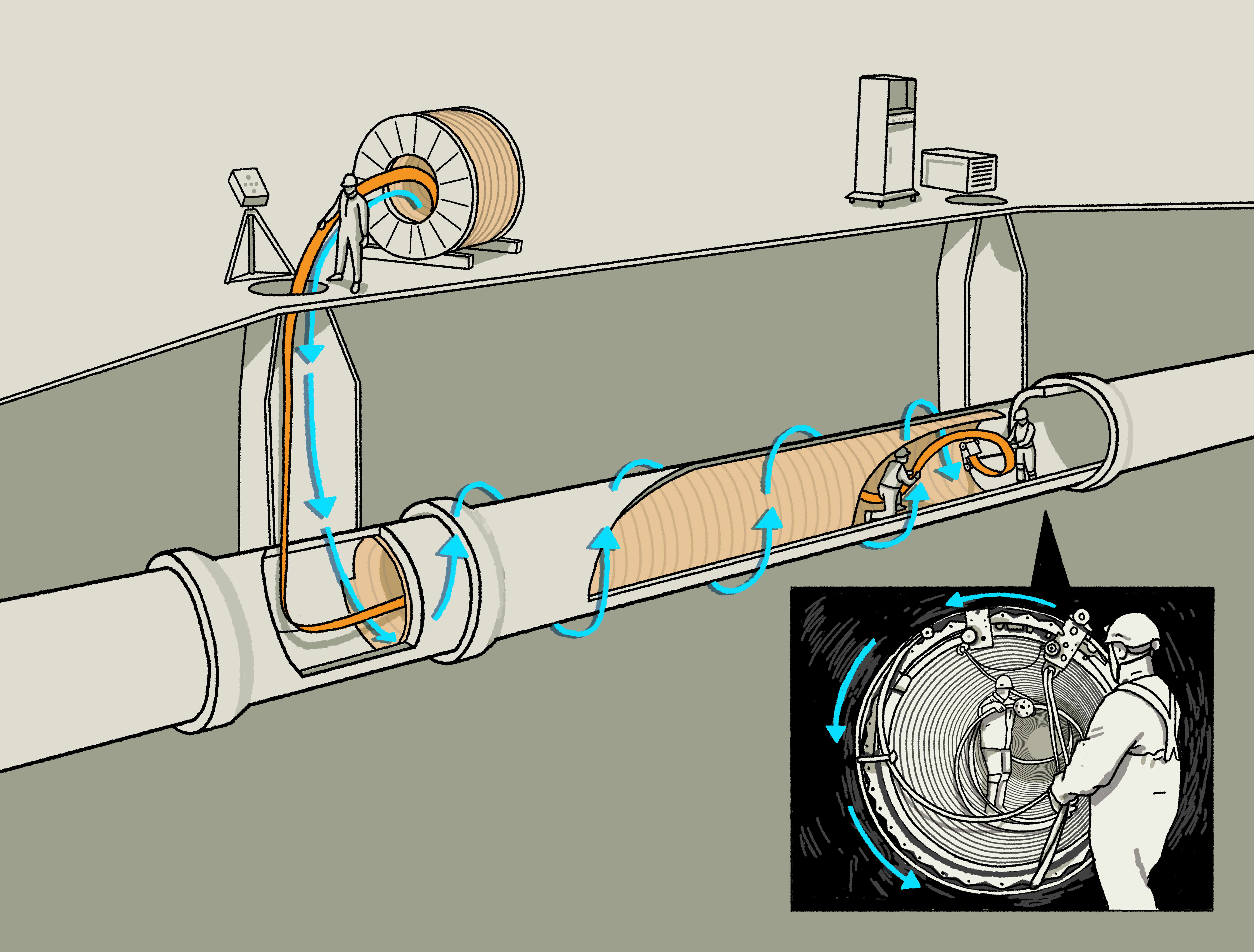

To begin the South Street rehabilitation project, fully equipped divers installed a submersible pump inside the interceptor sewer. The submersible pump, which can operate entirely underwater, is a key a part of a larger bypass system that diverts a portion of the water away from the interceptor sewer. With the bypass system in place, there is no need to disrupt services to the surrounding area since workers can continue the project while sewer flow continues.

For the next step of the project, the liner machine will be brought through a maintenance hole and assembled inside the interceptor sewer. The machine, which conforms to the shape of the sewer, then needs to be fed PVC material. This PVC material is easily shipped on site on spools and then fed to the lining machine through the existing maintenance holes. The machine will then construct the liner through a continuous winding process, interlocking the profile edges to form successive wraps of PVC. Space between the PVC and concrete wall of the sewer will be sealed with grout to help improve the structural integrity of the sewer.

Once the South Street project is complete, one thousand feet of deteriorated sewer will be reinforced with 4’ of PVC material. With the interceptor now impermeable to water, it will be less prone to potential overflow, which reduces the risk of flooding for the surrounding community. The finished project will also extend the overall lifespan of the interceptor sewer and prevent further damage from root intrusion. Implementing spiral wound lining is one of the many solutions DDC has found to efficiently maintain the City’s infrastructure while keeping costs and disruptions at a minimum.